×

- Definition

- BSC at a Glance

- History

- Advantages & Disavantages

- Strategy Maps

- BSC in Substance

- BSC and Dashboard

- BSC Principle

- The 4 Perspectives

- What is/is not the BSC

- The BSC Approach

- BSC vs Executive Dashboard

- US Style vs French Touch 1

- Gimsi Approach 2

- BSC & Gimsi 3

- Gimsi in Ten Steps 4

- Recommendations & Advice

- Comments on Strategy Maps

- Resources

- Total Performance Scorecards

- BSC Reference Books

- BSC Reference Web Sites

SIX SIGMA, 6 Sigma principle

19 May 2025

By Alain Fernandez

Share

Share

»»»» executive-dashboard.org is for sale »»»»

Using the Balanced Scorecard and GIMSI®

What is the 6 Sigma principle?

If we can measure, we can correct

6 Sigma method offers technics and tools in order to improve drastically capability of processes, while reducing defects at the same time. Originally oriented towards production processes, the method searches for absolute regularity.Variability is indeed a source of client dissatisfaction.

The customer expects a product with a certain quality, according to a specific standard.

Not being up to guarantee the whole production respecting this standard is particularly costly for the company.

If we can measure, we can improve

In fact, final quality variability is mainly the consequence of components (of the products fabrication) instability, of work procedures imprecision and more globally of processes complexity.Six Sigma imposes to keep in the limitations by applying the following principle:

If you can measure how many defects you have in a process, you can systematically figure out how to eliminate them and get as close to zero defects as possible.In other words, to sum up: If it can be measured, it can be corrected. The objective being to refocus the curve on the target.

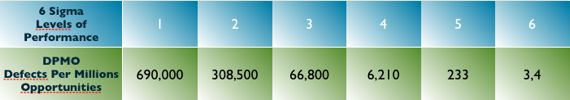

6 Sigma levels of performance

In the end, 6 Sigma doesn't allow more than 3.4 defects per million opportunities for each product or service.

Recommended reading

What is Lean Six Sigma?

What is Lean Six Sigma? M.L. George D. Rowlands B. Kastle

Mc Graw Hill

»»»» executive-dashboard.org is for sale »»»»

Using the Balanced Scorecard and GIMSI®

Share...

Share...

(total partages cumulés > 185)

- Definition

- BSC at a Glance

- History

- Advantages & Disavantages

- Strategy Maps BSC in Substance

- BSC and Dashboard

- BSC Principle

- The 4 Perspectives

- What is/is not the BSC

- The BSC Approach BSC vs Executive Dashboard

- US Style vs French Touch 1

- Gimsi Approach 2

- BSC & Gimsi 3

- Gimsi in Ten Steps 4

- Recommendations & Advice

- Comments on Strategy Maps Resources

- Total Performance Scorecards

- BSC Reference Books

- BSC Reference Web Sites